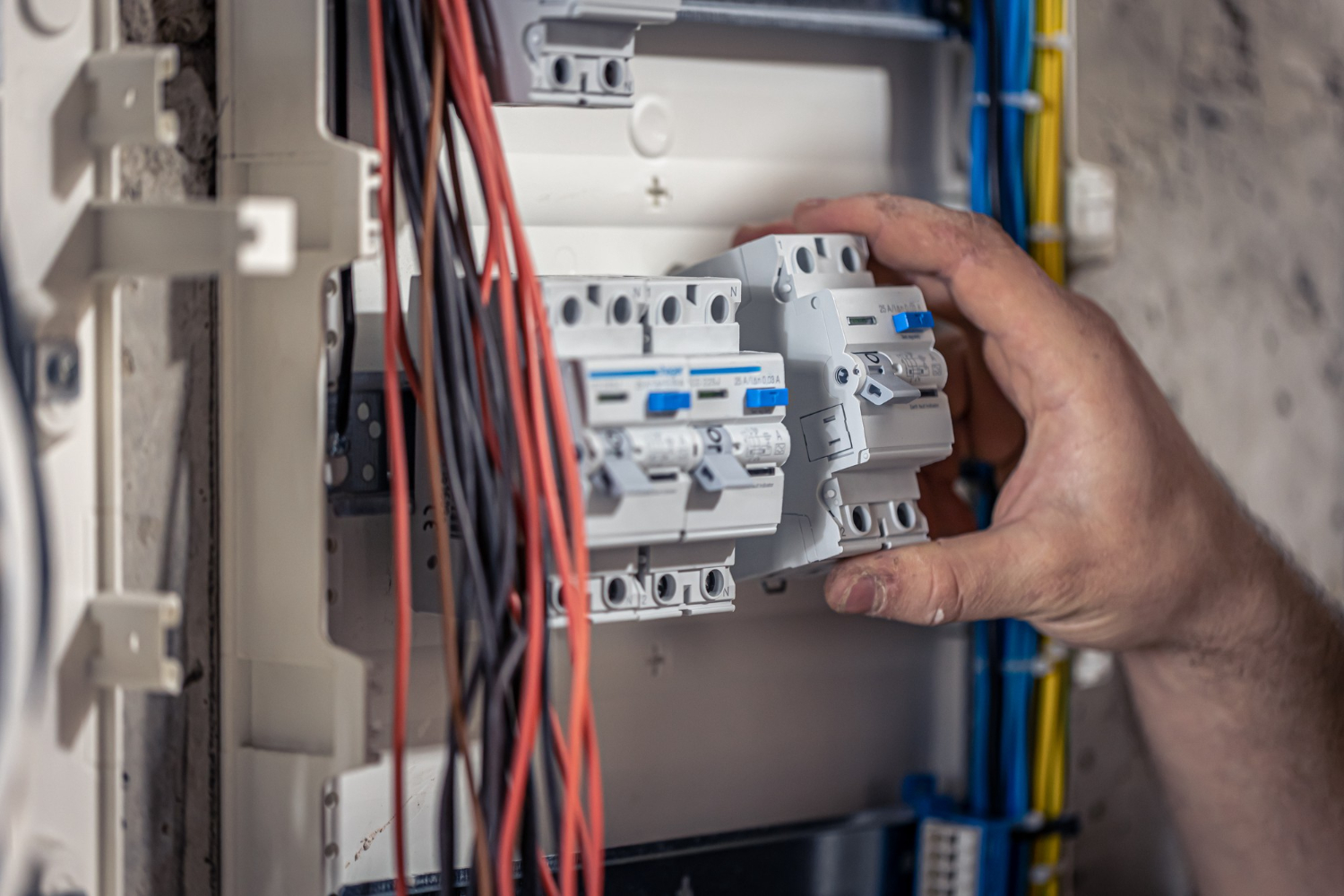

Industrial electrical panels are utilized across numerous industries to direct electric currents among the many pieces of equipment within a facility. Communicating safety and work-related information effectively may mean the difference between a low incident rate as well as violations or injuries. As such, electrical panel labeling standards are necessary. Another way to avoid workplace injuries is to have a practical and systematic safety and facilities management program.

One of the simplest ways of labeling your electric panel is to use a label maker. Not only are these labels clear and very easy to read, but they will also last a long time if applied correctly onto a clean surface. Another great option is to use a permanent marker and write directly onto your electrical panel.

Is It Necessary to Label Electrical Panels?

The labeling and documentation obligations for commercial locations are heavily influenced by local laws, industry regulations as well and standardized business procedures. Electrical panels – as well as elements in a building – need to be marked with several different labels to highlight both safety and identifying information. Two of the biggest regulatory bodies that manage facilities management in the United States – together with systems – are the Occupational Safety and Health Administration (OSHA) together with the American National Standards Institute (ANSI).

What are the Standard Requirements of Electrical Panel Labeling?

The Occupational Safety and Health Standards oversee every aspect of work environments in the United States. Within these regulations, several sections are directly applicable to the safety and informational labeling of electrical panels as well as equipment:

- OSHA 1910.145(e)(2): “The phrasing of any sign should be read with ease. It should also be concise. The sign should provide enough information to be easily understood. The wording should make a positive suggestion and should be accurate.”

- OSHA 1910.145(f)(4)(ii): “Signal word needs to be legible from a distance of 5 ft (1.52m).”

- OSHA 1910.303(e): “Electrical equipment will not be utilized except where the following inscriptions have been put on the equipment: the manufacturer’s name and trademark, as well as other marking showing voltage, current, wattage or other ratings as required.”

How to Label a Panel the Correct Way

Your electrical panel has to be labeled carefully and consider rules about the description of each single line. Follow these steps to ensure that your panel is labeled properly:

- Each circuit has to be specifically identified.

- Do not utilize abbreviations or symbols to describe what is on each circuit.

- Fill in each line that is utilized.

- Do not use the same description for more than a single circuit.

ESD – Expert Electrical Products & Service

Electrical panel labeling standards are very specific to safeguard the safety of everyone who is in the building.

Electrical Supply Distribution (ESD) is the brainchild of co-owners Gabriel Brionez and Bryan Laurion. After years and years of working his way up in the ranks in the electrical industry, Gabriel decided to grow ESD and give his customers the service and support that he felt was missing in the electrical circuit breaker industry.

ESD can help you buy good-quality electrical products. Contact us today to check out our wide offering.